Material Planning and OEM tracking

What Is Material Planning and OEM tracking?

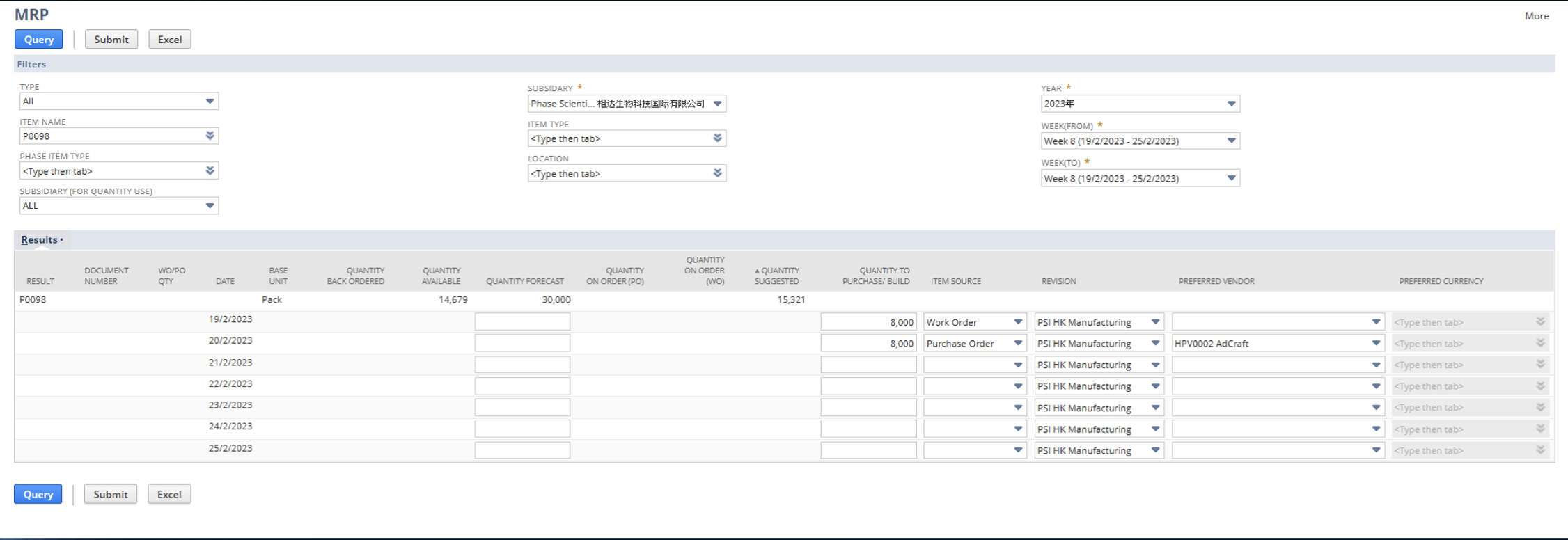

NetSuite Material Requirements Planning, or MRP, provides visibility into the inventory required to meet demand, helping your business optimize stock levels and fine-tune production schedules. NetSuite MRP accelerates the production process by determining what raw materials, components and subassemblies are needed, and when, to assemble finished goods, based on demand and bills of materials (BOMs).

Tailored for Company with OEM process.

Benefits

Material Planning and OEM tracking

Any company with OEM process will be benefited from:

- Efficiently Plan and Schedule Production. Ensure materials move through the work order quickly and customer orders are fulfilled on time.

- Single Source of Data. Integrated across the organisation eliminates the need to pull historical sales and existing inventory to build production flows.

- Accurately Calculate Production. Understand all of the components that go into each sub-assembly and how long it takes to complete each step.

Functions

OEM tracking: Tracking the product status in various OEM vendor

- Define the manufacturing process in BOM, allows the user to define the procedure/Production Place/Vendor for each Order

- Auto-generating PO/WO in various steps

- Keep track the logistics details for each International Transport

MRP (Materials Resources Planning)

- Customized interface for material/production planning with auto-suggested quantity to be built/purchased